MICRO-OPTICS & PHOTONICS

Applications

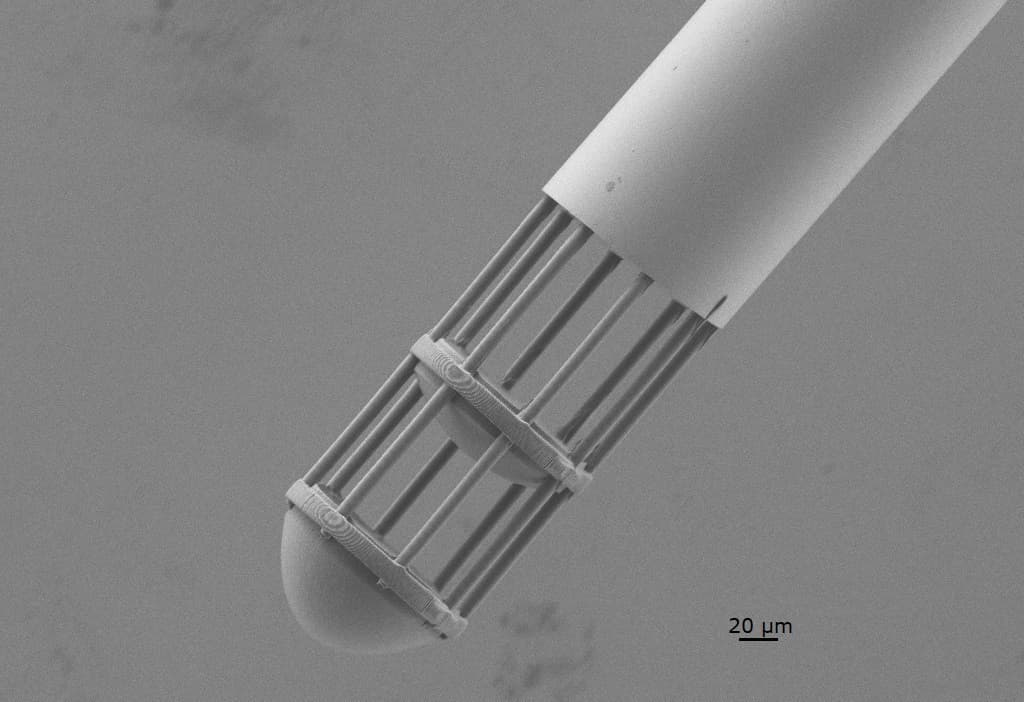

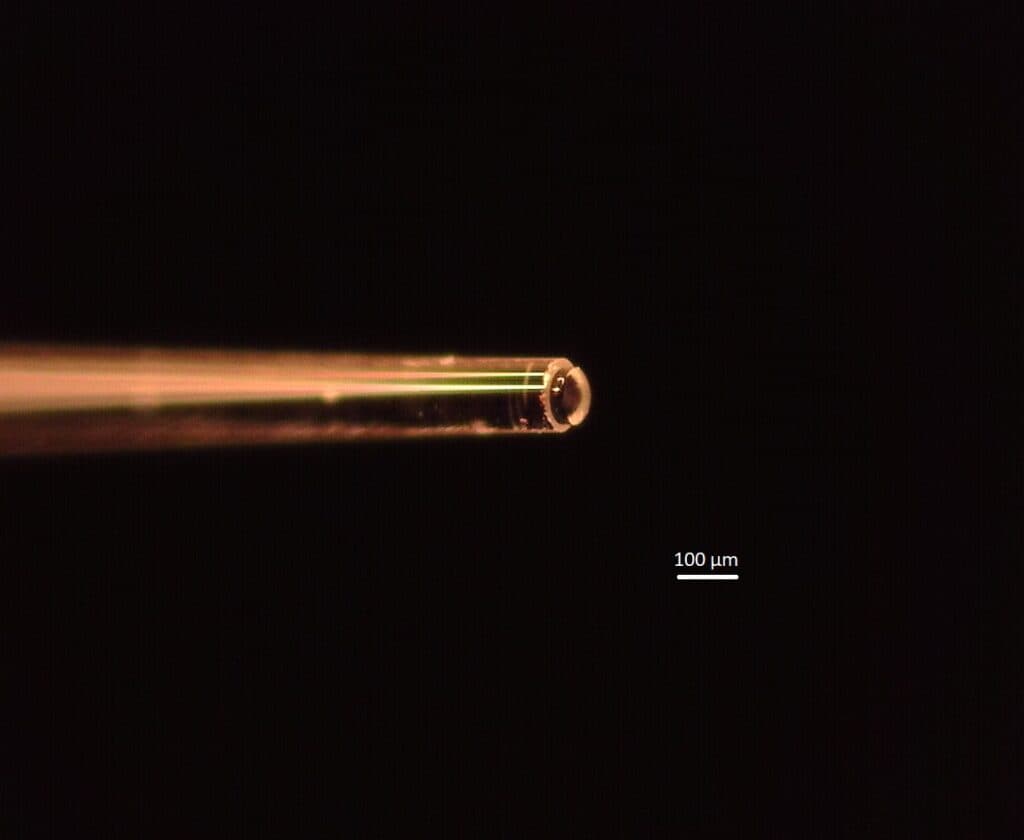

Micro-lenses spaced 100 µm and 200 µm over the tip of an optical fiber for transceivers applications. Pillars were realized at low resolution for faster printing, and lenses at high resolution to get a smooth surface. - Realized with microFAB-3D.Advanced

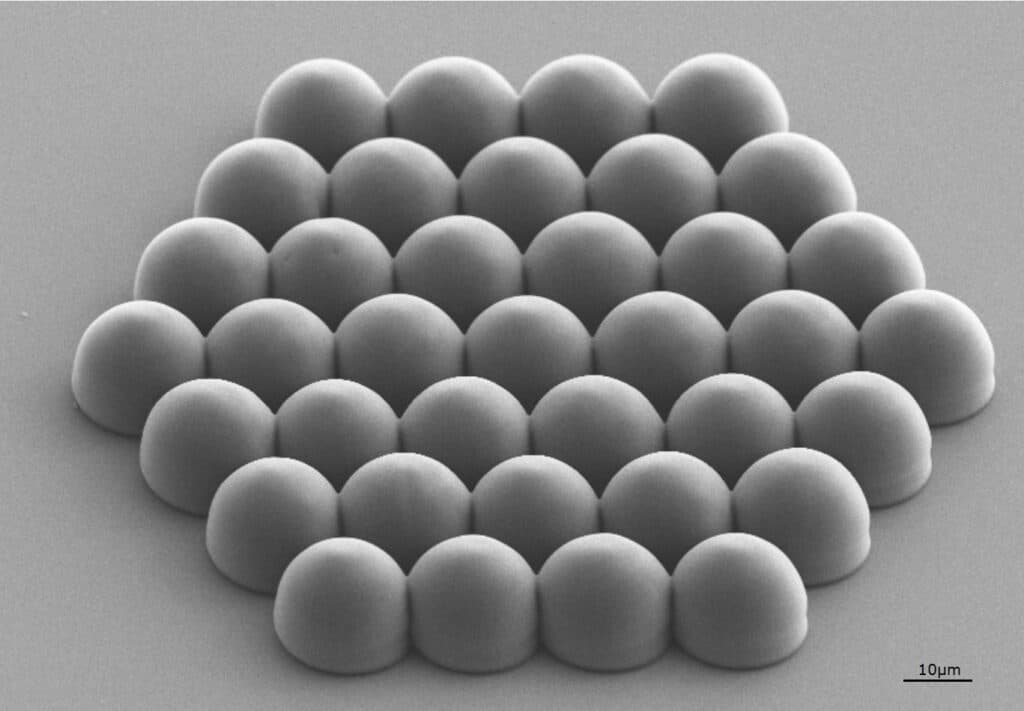

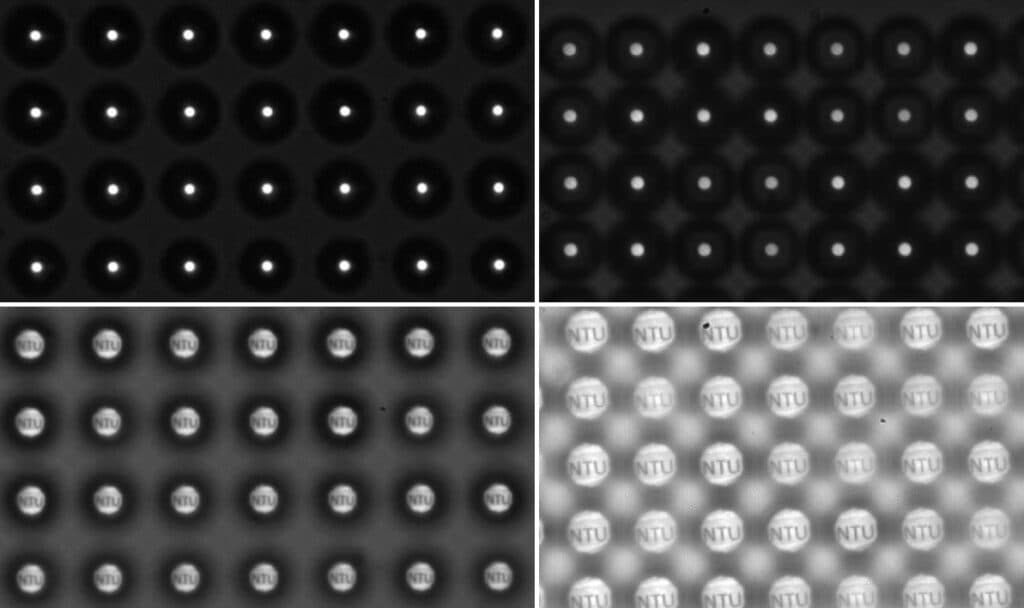

Array of 20-µm-wide micro-lenses.

Courtesy of A. Banyasz et al., ENS Lyon, CNRS - Realized with microFAB-3D.Standard

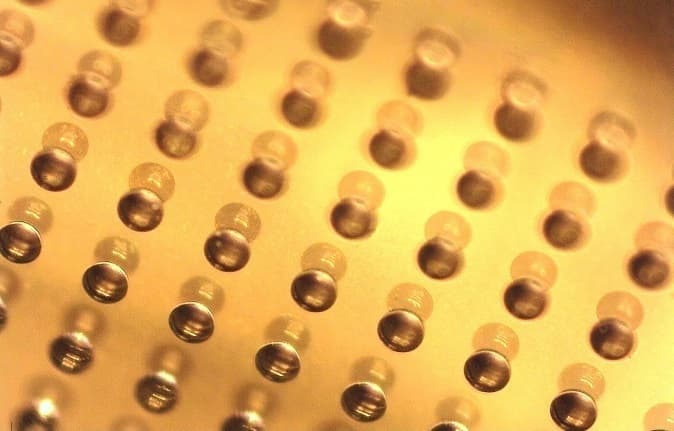

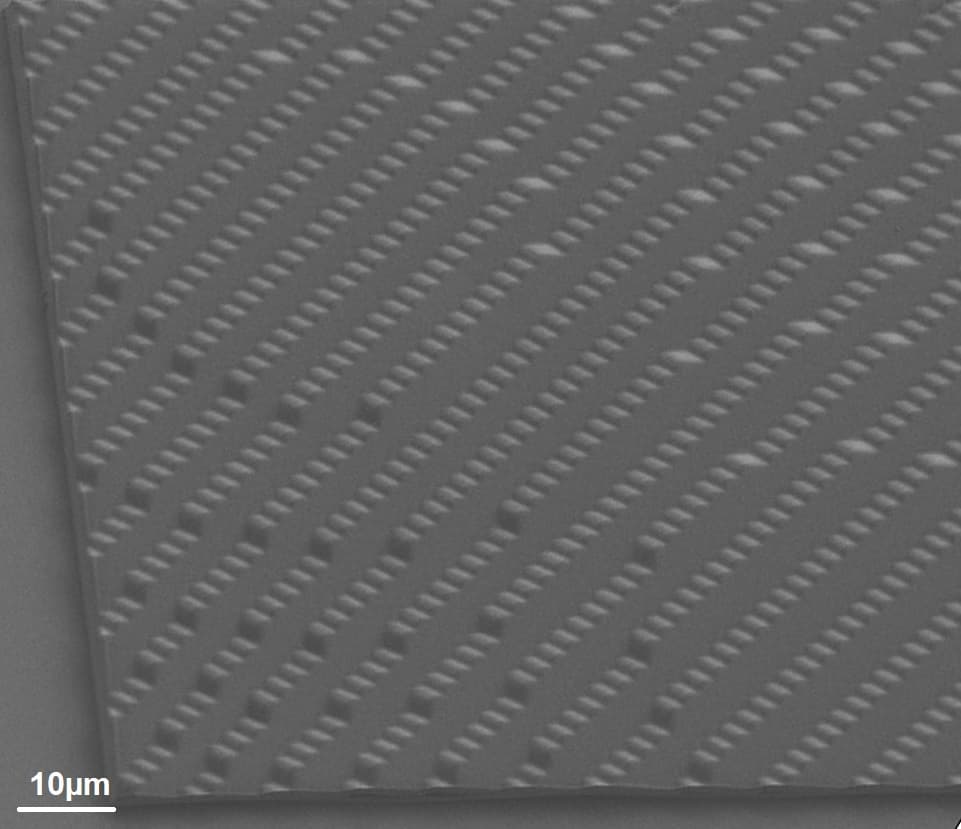

10x10 array of 150-µm-wide micro-lenses.

Courtesy of C. Aldebert - Realized with microFAB-3D.Advanced

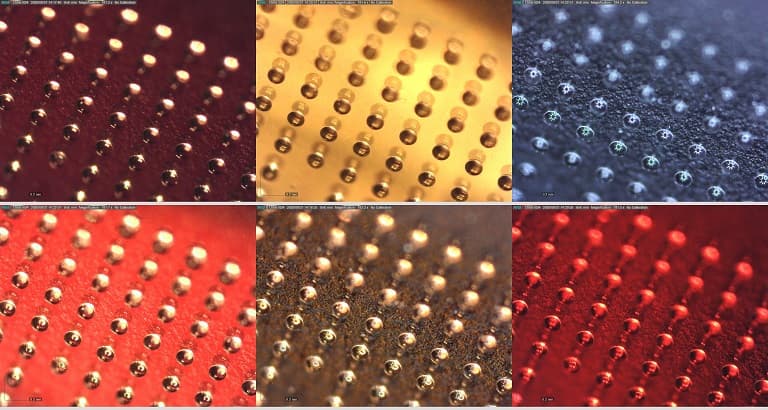

10x10 arrays of 150-µm-wide micro-lenses.

Courtesy of C. Aldebert - Realized with microFAB-3D.Advanced

Automatic large area micromanufacturing of Fresnel microlenses for microoptics applications.

Courtesy of TT. Chung et al., National Taiwan University - Realized with microFAB-3D.Advanced

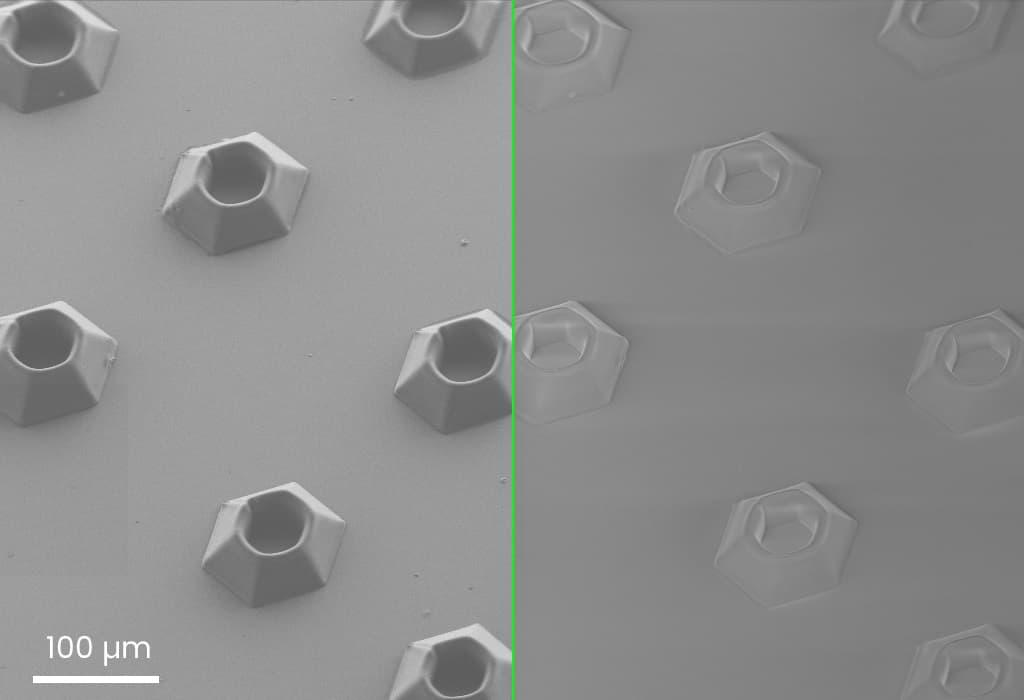

Array of OrmoComp micro-wells for single cell high resolution imaging - Realized with microFAB-3D.Advanced, in a collaboration with R. Galland, CNRS Bordeaux, France.

Optical focalisation by 3D-printed micro-lens magnetic actuation.

Courtesy of V. Vieille et al., G2ELab (G-INP/Néel/CNRS) - Realized with microFAB-3D.Standard

Single lens printed on the tip of an optical fiber - Realized with microFAB-3DAdvanced

Diffractive Optical Element (DOE)