Key features

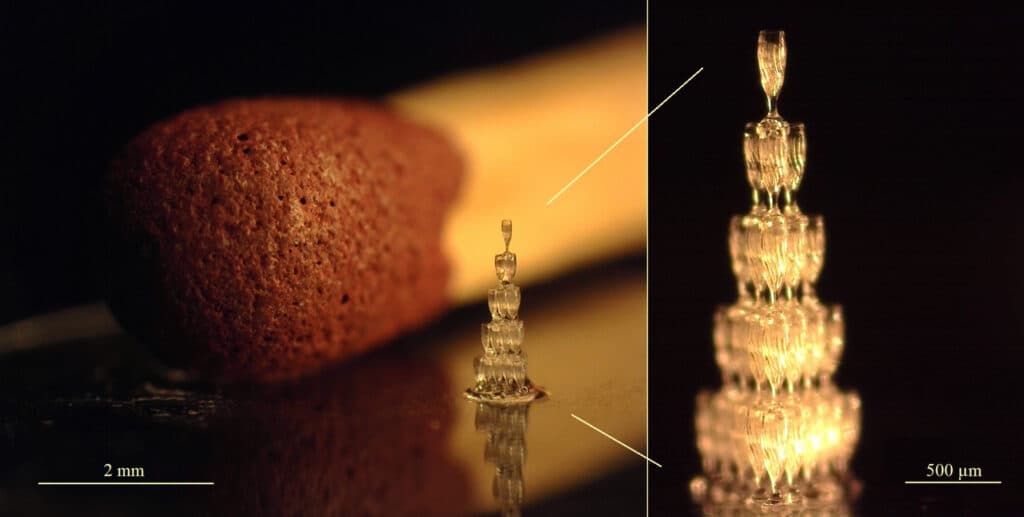

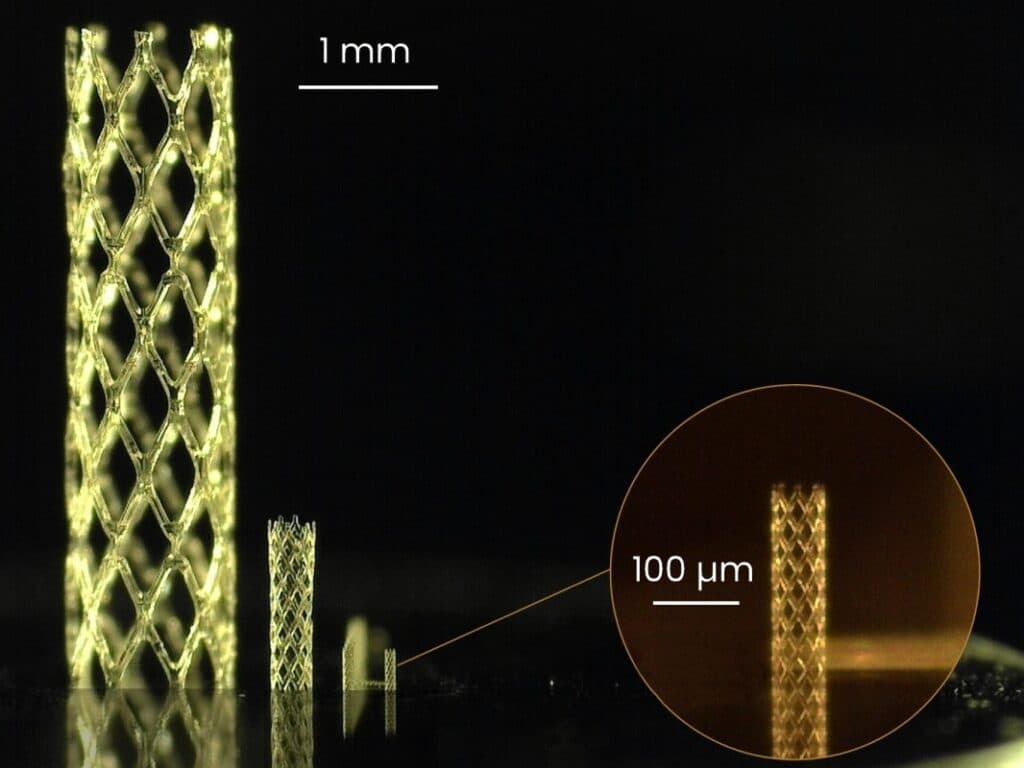

microFAB-3D is an ultra-high resolution 3D-printing system, based on two-photon polymerization direct laser writing technology. With a minimal feature size down to 0.2-microns-wide, this machine opens new perspectives in microfluidics, micro-optics, cells culture, micro-robotics or meta-materials. Open and evolutive, it can be adapted to fit your needs.

3D-PRINT AT THE HIGHEST RESOLUTION

Feel the power of two-photon polymerization and print features down to 200 nanometers wide! The highest resolution is achievable with any configuration of microFAB-3D, from Basic to Advanced.

A UNIQUE TECHNOLOGY

Our innovative micro-printing systems rely on industrial lasers with unique characteristics, in terms of highest printing-resolution, compactness, cost-efficiency and flexibility of use. It also provides better reliability because these industrial lasers last a very long time with no need for yearly maintenance.

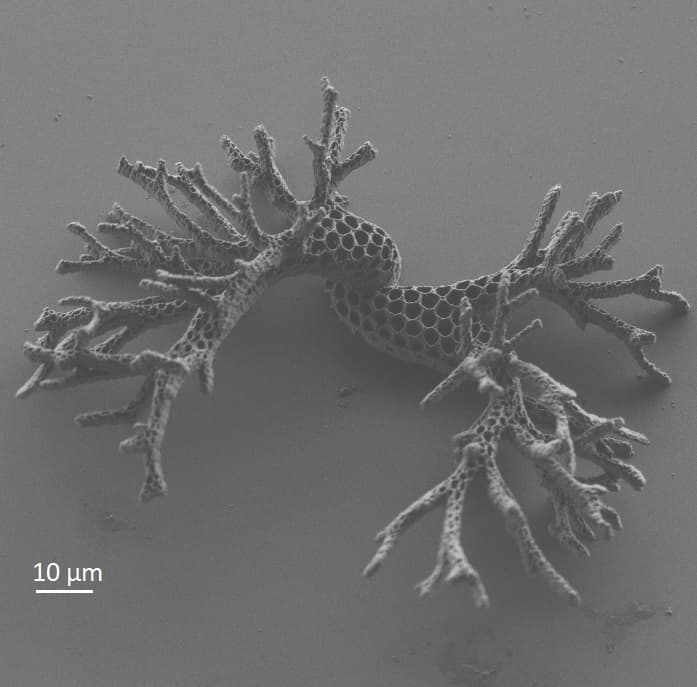

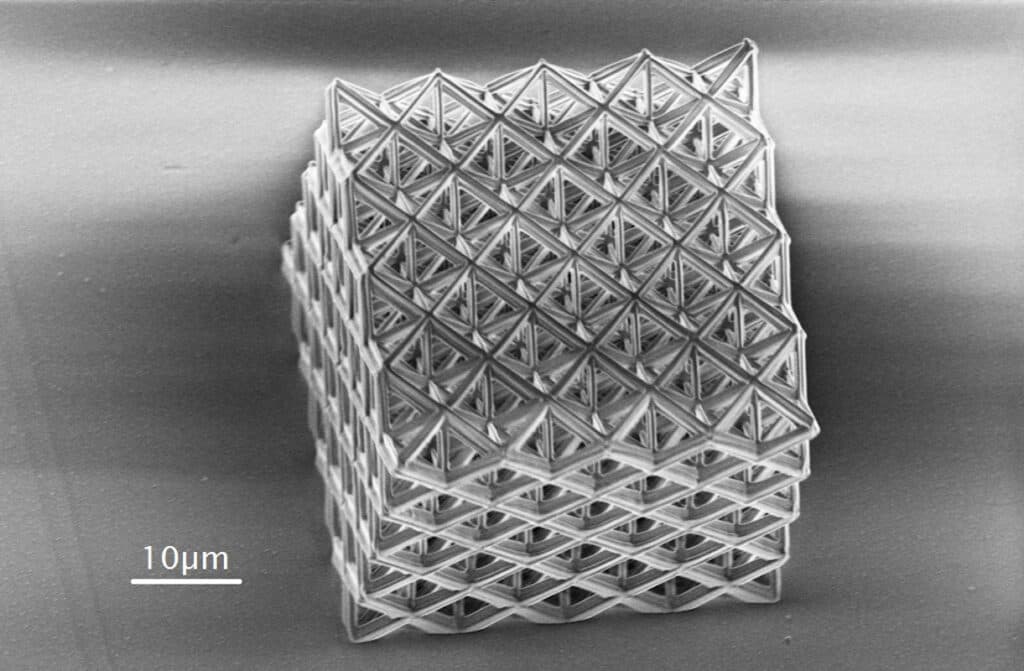

PRINT THE MOST COMPLEX STRUCTURES

Unlike conventionnal 3D-printing technologies, our direct laser writing technology allows us to get rid of the traditionnal "layer-by-layer" approach. You can therefore print the most complex architectures, with no need of support material or post processing, and enhanced mechanical properties.

ADAPT THE RESOLUTION THROUGHOUT THE FABRICATION

Our software allows you to adapt the printing resolution during the fabrication. Use a big voxel to print faster, and a smaller one to realize the complex features!

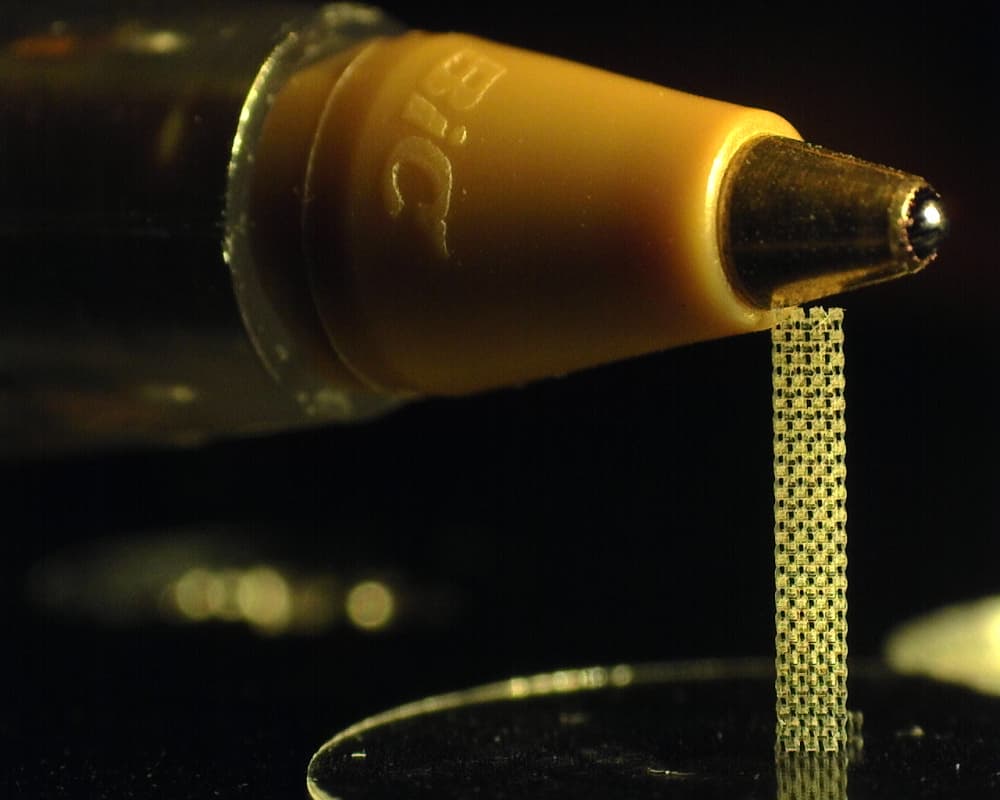

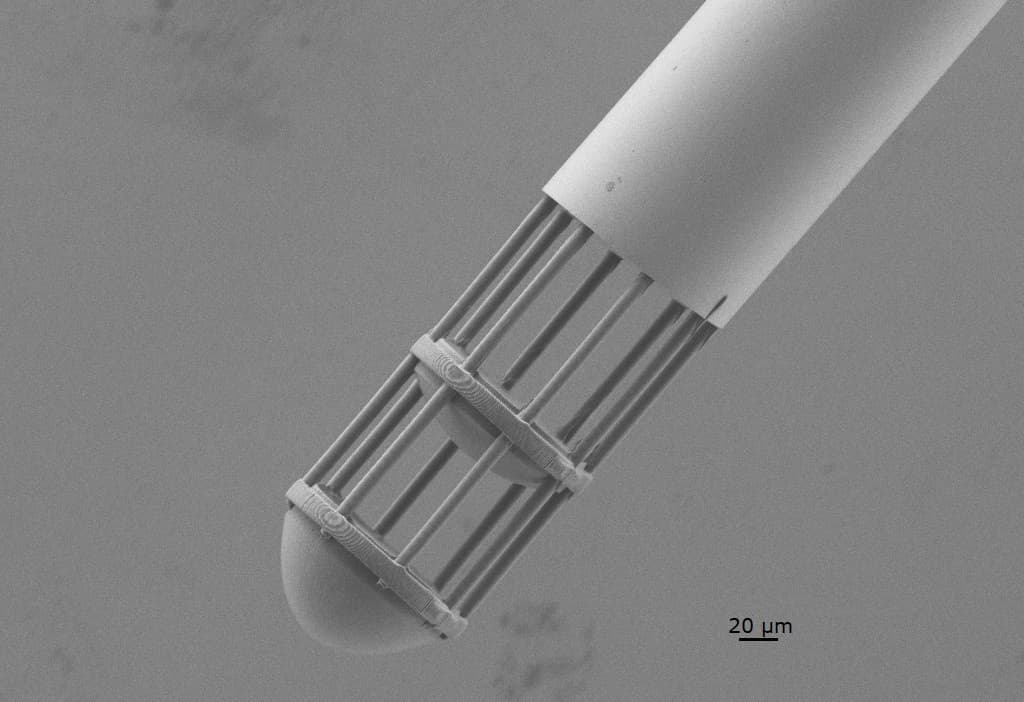

PRINT ON THE TIP OF OPTICAL FIBERS

Align and print on structured substrates, or directly on the tip of optical fibers of various dimensions, at a precision of 1 µm. Custom holders are available for unconventional ferrules or automated printing on multiple fibers.

UPGRADE FROM STANDARD TO ADVANCED EASILY

microFAB-3D can evolve easily depending on your needs and resources. You may explore 3D-microprinting at high resolution with microFAB-3D.Standard, and upgrade it afterwards to microFAB-3D.Advanced for large range replications, Voronoï structures, a second laser, and many other features.

Technology

microFAB-3D systems use a unique green-laser based two-photon polymerization technology to create 3D objects at unprecedented precision.

With this technology, Microlight3D can bring to the market a system with unique characteristics, in terms of highest printing-resolution, compactness, reliability and flexibility of use.

Specifications

Software

Microlight3D has developed its own software suited to generative 3D slicing and TPP microfabrication, to overcome the limits of the conventional "layer-by-layer" approach and create stunning microstructures.

Great efforts have been made on our microfabrication software, to give you an especially easy to use interface.